-

合金牌号:

ER4047

-

状态:

铝焊丝

-

直径:

0.8-4.0mm

-

截面厚度:

1.0-4.0mm

-

截面宽度:

2.0-5.0mm

-

生产区域:

国产

-

铝含量:

合金

-

加工方式:

气保护,氩弧焊

-

用途:

焊接以下铝合金——汽车铝水箱、中冷器、散热器、铝合金客车窗、自行车车架、铝件维修。

产品描述

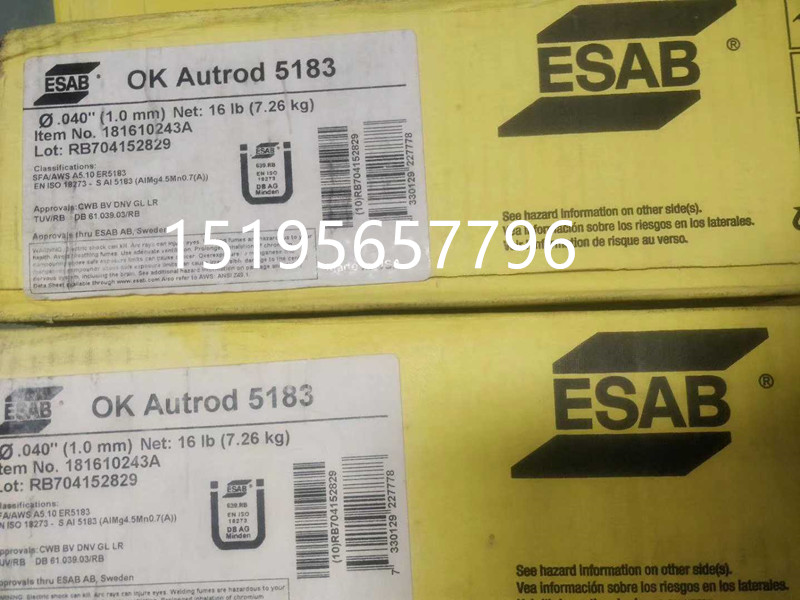

OK Autrod 4047铝硅焊丝

品牌:瑞典伊萨

铝焊丝标准:GB/T10858-2008 AWS A5.10

焊丝直径:1.2、1.6、2.0、2.4、3.0、3.2、4.0、5.0(mm)

焊丝盘尺寸:D300(9kg)、D270(7kg)、D200(2kg)、D100(0.5kg)

包装状态:盘丝、直条

焊丝特点:12%硅含量,流动性好,焊接温度低。

推荐焊接方法:钎焊(俗称:氧气焊、火焰焊),配201铝焊粉。

焊接应用:焊接以下铝合金——汽车铝水箱、中冷器、散热器、铝合金客车窗、自行车车架、铝件维修。

OK Autrod 4047

GMAW

OK Autrod 4047 was originally developed as a brazing alloy to take advantage of its low melting point and narrow freezing range. In addition, it has a higher silicon content than OK Autrod 4043, which provides increased fluidity and reduced shrinkage. The alloy produces bright, almost smut-free welds. Hot cracking is significantly reduced when using OK Autrod 4047 as a filler alloy. The alloy can be used in applications with sustained elevated temperatures. Non-heat treatable.

Welding current

DC( )

Classifications Approvals Typical all weld metal composition, %Typical mech. properties all weld metal

SFA/AWS A5.10 ER4047

EN ISO 18273

S Al 4047 (AlSi12)

CWB AWS A5.10 (Item number ending with A)

Si 12,0 Mn <0,15 Cu <0,05 Ti <0,15 Zn <0,20 Fe <0,6

Wire composition

Yield stress, MPa 80

Tensile strength, MPa 170

Elongation, % 12

Elongation, % 12

Diameter, mm 0,9 1,2 1,6

Arc voltage, V 13-24 20-29 25-30

Welding current, A 60-170 140-260 190-350

Wire feed, m/min - 6-13 4,5-7,5

Deposition rate kg weld metal/hour - 1,1-2,4 1,5-2,5

品牌:瑞典伊萨

相关推荐

相关推荐

免责申明:以上所展示的信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责,铝道网对此不承担任何保证责任。为保障您的利益,我们建议您选择铝道网的 铝业通会员。友情提醒:请新老用户加强对信息真实性及其发布者身份与资质的甄别,避免引起不必要

风险提示:创业有风险,投资需谨慎。打击招商诈骗,创建诚信平台。维权举报:0571-89937588。

- 达森特焊接材料(苏州)有限公司

- 经营模式:代理经销商

- 主营:铝焊条,铝焊丝,铝钎焊料,焊剂,焊粉,焊膏

- 地区:江苏 苏州

联系方式

李杰

手 机:点击查看

电 话:点击查看

传 真:点击查看

地 址: