产品描述

一、设备用途:The application

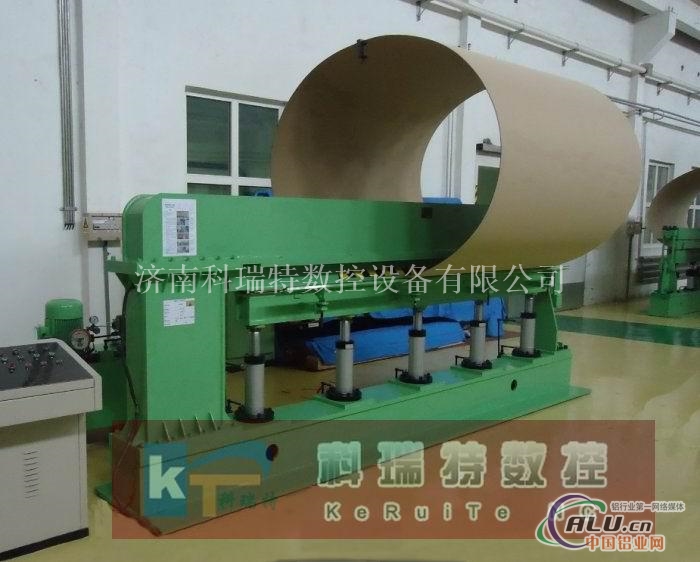

本设备是为变压器行业大型绝缘纸筒热压粘合而设计,是能对卷圆后的绝缘纸筒在一定的压力和温度条件下进行热压粘合成型的专项使用加工设备。

It is designed especially for bonding the large cylinder of insulation pressboard in the field of transformer, i.e. the hot sticking on the juncture of the insulation pressboard rolled into cylinder under certain pressure and temperature conditions.

二、主要技术参数 The main technical parameters

1、粘接纸板厚度: The pressboard’s thickness 1.5—6mm

2、热粘纸筒非常大长度: The Max. Length of cylinder to stick hotly 3200mm

3、粘合接口非常大宽度: The Max. width of overlapping part: 140mm

4、热粘纸筒直径范围: The range of Dia. for cylinder to stick hotly Φ400—Φ3000mm

5. 系统压力: The system pressure8MPa

6、加热方式:电加热,工件粘合温度70co—110c°可调

The heating method: Electrical heating, and the bonding temperature 70co—110c°,adjustable.

三、主要机构性能 The performance of the main structure

1、本专项使用机床农业生产体系械部分(机座、压梁)、液压系统、电气控制、加热等四大部分组成。机座、压梁采用钢板焊接并经过振动时效处理,液压站、液压缸采用国内优异产品。

This machine has four major components such as mechanical part (pedestal and beam), hydraulic system, electrical cool and heating system. The pedestal and the beam is made by steel plates welded and treated by VSR. And the hydraulic and the hydraulic cylinders are selected Chinese products with high-quality.

2.液压缸采用上顶式,液压缸的数量要保证压梁、模具有足够的强度和刚度,不能有用眼发现明显的变形,液压系统不准渗漏油。

The cylinders are upward and their number should guarantee the beam and mold to have enough strength and stiffness. The visual deformation and leaking oil are not permitted.

3、机床具有温度、压力、时间系数的设定及调控功能。

This machine has the setting of temperature, pressure and time coefficient as well as the function of cool and regulating.

4、机床带有圆筒支撑架。

The machine has the cylindrical support frame.

相关推荐

相关推荐

免责申明:以上所展示的信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责,铝道网对此不承担任何保证责任。为保障您的利益,我们建议您选择铝道网的 铝业通会员。友情提醒:请新老用户加强对信息真实性及其发布者身份与资质的甄别,避免引起不必要

风险提示:创业有风险,投资需谨慎。打击招商诈骗,创建诚信平台。维权举报:0571-89937588。

- 济南科瑞特数控设备有限公司

- 经营模式:制造商+贸易商

- 主营:母线加工机,铜排加工机,变压器绕线机,高低压绕线机,圆剪机,瓦楞机,纸板圆剪机,母排加工机

- 地区:山东 济南

联系方式

留言咨询