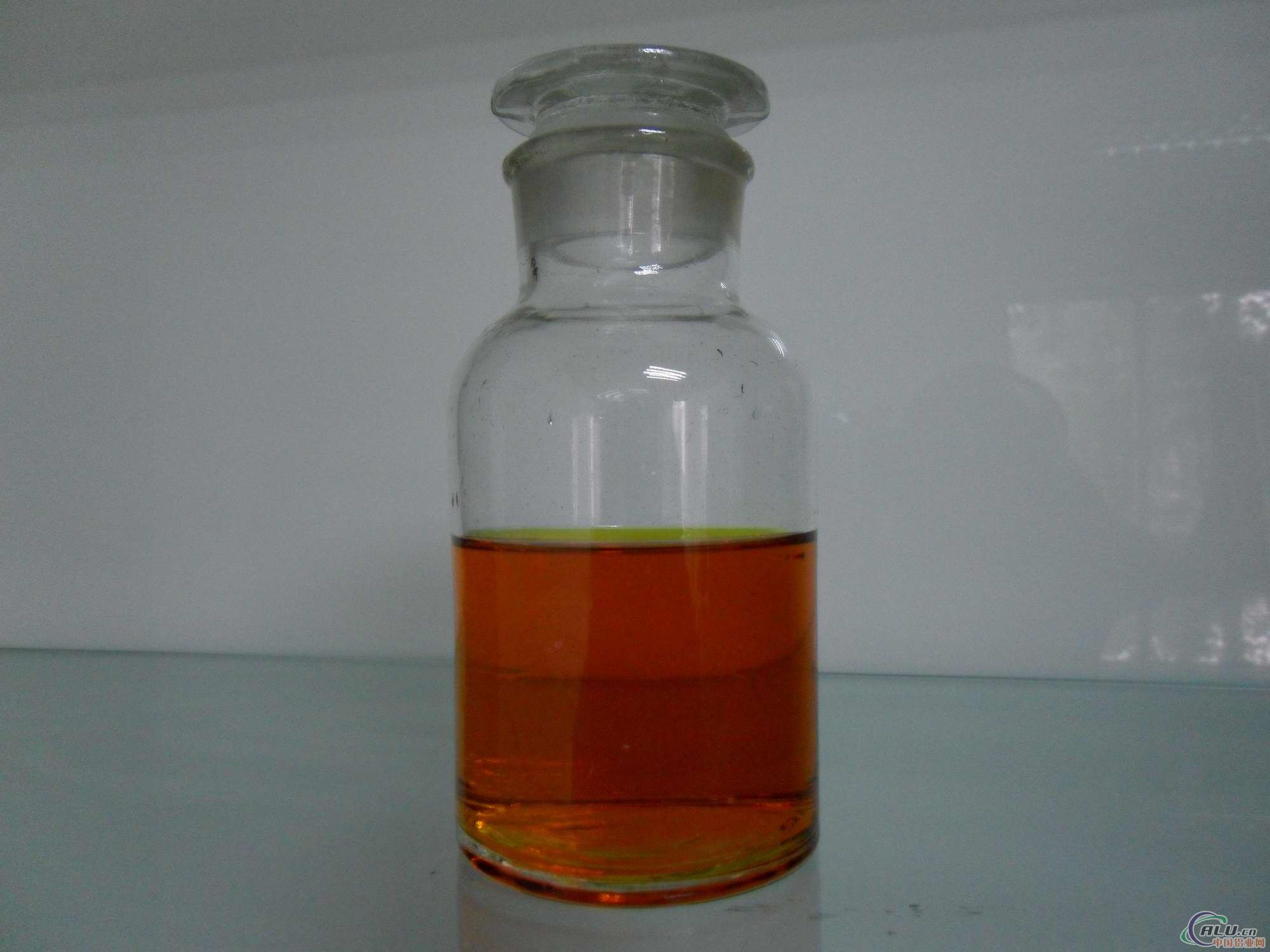

产品描述

JB-E01长寿碱蚀添加剂

u 产品特性

1.适合的表面活化剂、缓蚀剂易于产品出槽时滴流,有效防止流痕产生。

2.独特的整平剂、光亮剂使处理后产品表面平整光亮有利于着色料底色更加鲜艳。

3.适量的抑雾剂有效地抑制碱雾的产生,有利于改善车间环境。

u 开槽参数

NaOH :50~60g/L

JB-E01:20~30g/L

u 控制参数

游离碱 :45~60g/L AL3+ :15~25 g/L

温度 :45~60℃ 时间 :1~5 min

u 维护和管理

1.每天分析槽液浓度并根据结果及时调整,补加比例为氢氧化钠:JB-E01=5:1。处理100m2铝材约消耗JB-E01:0.5~1.0kg。

2.正常生产时因带出损耗导致液面降低补加水则需添加相应比例的氢氧化钠和JB-E01。

3.不生产时加盖槽液以防污染。并保温≥35℃以防铝离子水解。

u 包装、贮存及保质期

25kg塑料桶装;避光、避酸、轻放、密封置干燥,阴凉处,防止泄漏。室温存放1年。

JB-E01 Etching Additive

u Product Features

1.Contains active agent to prevent dripping mark on work piece and corrosion inhibitor.

2.With complex and appropriate leveling agent and brightener. Work piece surface will be bright, smooth and clean to enhance coloring ability.

3.Contains fog and smoke inhibitor to help improve workshop environment.

u Tank set up parameters

NaOH :50~60g/L

JB-E01:20~30g/L

u Coolling parameters)

Free alkali :45~60g/L AL3+ :15~25 g/L

Temperature :45~60℃ Time :1~5 min

u Maintenance and cool

1.Analyse bath conceation once a day. Add and maintain sodium hydroxide to JB-E01 ratio at 5:1. Typical consumption of JB-E01 is 0.5 to 1.0kg per 100mm2 of aluminum surface treated.

2.Any addition to loss of bath solution due to evaporation or dragged out, correct chemical ratio must be maintained.

3.Cover bath if not running production to prevent contaimination. Solution temperation should be maintained at ≥35℃.

u Packing and Storage

25kg plastic bucket;Protect form heating, avoid acid, keep sealed in a dry, cool place and prevent leakage. The product shelve life is 1 year under room temperature

相关推荐

免责申明:以上所展示的信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责,铝道网对此不承担任何保证责任。为保障您的利益,我们建议您选择铝道网的 铝业通会员。友情提醒:请新老用户加强对信息真实性及其发布者身份与资质的甄别,避免引起不必要

风险提示:创业有风险,投资需谨慎。打击招商诈骗,创建诚信平台。维权举报:0571-89937588。